Home |

|

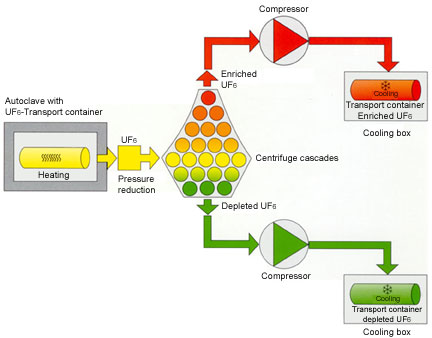

After chemical conversion of natural uranium ore concentrate into uranium hexafluoride (UF6), the UF6 is put into standard containers and sent to an enrichment plant. At the enrichment plant, the transport container and its UF6 contents are put into a heating chamber, or "autoclave," to vaporise the UF6. After pressure reduction by control valves, the UF6 is fed into the cascades. A cascade is composed of centrifuges connected by pipes both in series and in parallel. Inside the cascade, the gas stream is divided into two output streams by the centrifuges. One stream is enriched in uranium 235 (U-235) and the other depleted in U-235. The UF6 gas, which is at very low pressure, is withdrawn from the cascade by compressors that raise the pressure of the gas. It is piped to transportation containers in cooling boxes, where the UF6 solidifies. The separation effect of a cascade is expressed in separative work units calculated by a standard formula. Seperative work is defined as a measure of the effort required in an enrichment facility to separate uranium of a given U-235 content into two fractions, one with a higher percentage and one with a lower percentage of U-235. The unit of separative work is the kilogram separative work unit (kg SWU), or separative work unit (SWU) for short. The initial material is called the "feed." The fraction with a higher proportion of U-235 is called the "product," the other is called the "tails." The higher the U-235 content of the enriched uranium and the lower the U-235 content of the depleted uranium, the more SWUs are required.

1Source: www.urenco.com |

||

|

|

|